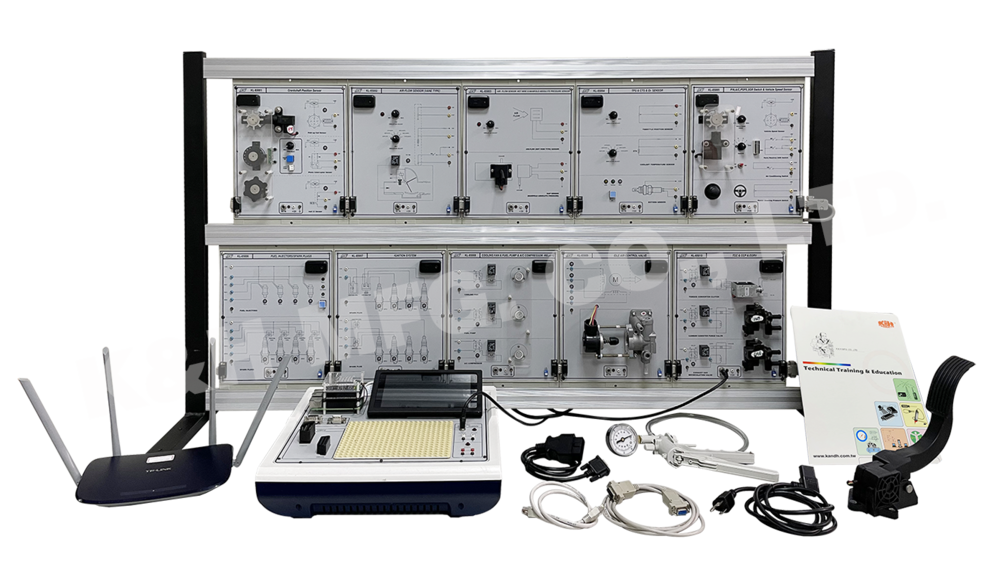

KL-810 Smart CAN BUS Training System

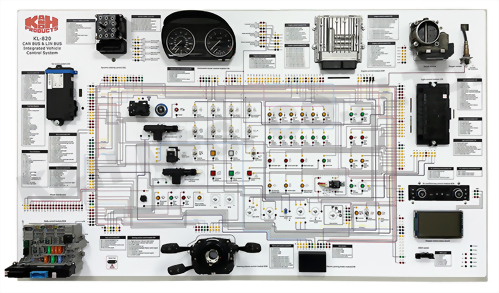

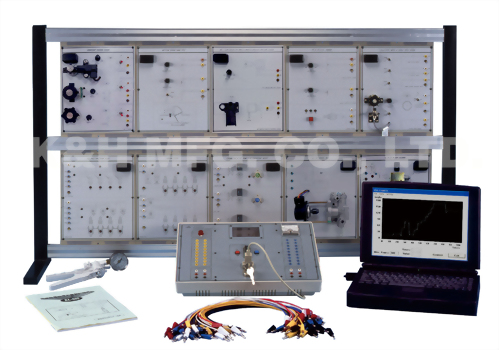

The Smart CAN BUS Training System has one CAN BUS network human-machine interface (HMI) platform and 10 experimental modules. In addition to providing CAN BUS signal input /output, the presentation of CAN BUS data formats and the display of various measured waveforms can be performed on the platform, following OBD-II standard in vehicles , it is able to simulate the operation of air flow, temperature, fuel system, ignition system, idle air control valve, and other sensor characteristics…etc.

1. Engine

Speed Sensors

(1) Pick-up Coil Type Engine Speed Sensor (NE Signal)

(2) Photo-Type Engine Speed Sensor (PHO Signal)

(3) HALL IC Engine Speed Sensor (HALL Signal)

2. Air-Flow Sensors

(1) Vane Air-Flow Sensor (VAF)

(2) Hot Wire Mass Air-Flow Sensor (MAF)

(3) Manifold Absolute Pressure Sensor (MAP)

3. Throttle Position Sensor

4. Coolant Temperature Sensor

5. Oxygen Sensor

6. Vehicle Speed Sensor

7. Third Gear Switch

8. Park/Neutral Switch

9. Air Conditioning Switch

10. Power Steering Pressure Switch

11. Injector Circuit

12. Computer-Controlled Ignition System

13. Cooling Fan Relay Circuit

14. Fuel Pump Relay Circuit

15. A/C Compressor Relay Circuit

16. Idle Air Control Valve

17. Torque Converter Clutch

18. Carbon Canister Purge Valve

19. Exhaust Gas Recirculation Valve

1. Provide

teaching and training frameworks for automotive sensor measurements and

actuator operation control.

2. The smart integrated training system transmits and receives CAN BUS signals

and provides a learning environment for verifying the system theory.

3. Constructing combination experiments via CAN BUS cable.

4. Equipped with DB9, OBD-II connectors, a simulated vehicle battery with 12V

power supply etc., which are provided for related CAN BUS network designs and

development environments.

5. Each experimental module is equipped with a fault troubleshooting switch.

6. The HMI platform provides CAN BUS signal input/output and interaction with

the experimental module. It integrates electronic signals and digital data

referencing environments, which facilitate interpretation and related research.

7. The HMI platform is an open source system that supports the CAN BUS

development environment.

8. Present the integrated application of IoT (Internet of Things) and CAN BUS

through the web GUI of HMI platform.