KR-115B Refrigeration Cycle and Heat Pump System with HMI

Model :

KR-115B

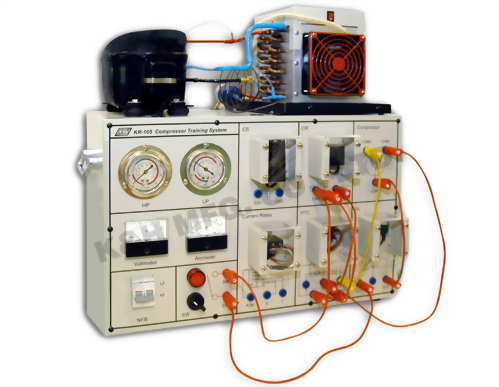

KR-115B is designed to learn the theory of Heat Transfer in refrigeration engineering. With proper setup, KR-115B can be emulated as a Refrigeration or Heat Pump system. All system components are mounted on the front panel so students can directly observe, touch the components, and hear the noise produced by the components while it is running under either Refrigeration or Heat Pump cycle.

KR-115B offers three expansion devices available for the refrigerant to pass through; they are pressure expansion valve, capillary tube, and thermal expansion valve. Students can use the control panel to switch the preferred expanding path from three expansion devices and compare the corresponding performance under Refrigeration or Heat Pump cycle.

The state of the refrigerant can be clearly observed through 6 sight glasses at different phases of the Refrigeration / Heat Pump cycle. Student must use the valves to lead the refrigerant to the appropriate flowing direction so that the system can operate in corresponding cooling / heating condition. If students mislead the refrigerant to wrong flowing direction, the pressure protection switches will detect the conflict and halt the compressor to prevent the system from being damaged.

Using HMI control system, touch panel can easy to control and check system's experiment status for students, the panel will display system working status, temperature and pressure numbers unit easy to choice and change.

KR-115B offers three expansion devices available for the refrigerant to pass through; they are pressure expansion valve, capillary tube, and thermal expansion valve. Students can use the control panel to switch the preferred expanding path from three expansion devices and compare the corresponding performance under Refrigeration or Heat Pump cycle.

The state of the refrigerant can be clearly observed through 6 sight glasses at different phases of the Refrigeration / Heat Pump cycle. Student must use the valves to lead the refrigerant to the appropriate flowing direction so that the system can operate in corresponding cooling / heating condition. If students mislead the refrigerant to wrong flowing direction, the pressure protection switches will detect the conflict and halt the compressor to prevent the system from being damaged.

Using HMI control system, touch panel can easy to control and check system's experiment status for students, the panel will display system working status, temperature and pressure numbers unit easy to choice and change.

1. Refrigeration circulation system with capillary tube

2. Refrigeration circulation system with pressure expansion control valve

3. Refrigeration circulation system with thermal expansion control valve

4. Reverse cycle heat pump system

5. Reverse cycle heat pump system without refrigerant receiver

6. Drawing Mollier Chart

7. Calculating system performance

8. Comparison of system performance

9. Comparison of energy between cooling and heating experiments

10. Coefficient of performance (COP) and energy efficiency ratio (EER)

2. Refrigeration circulation system with pressure expansion control valve

3. Refrigeration circulation system with thermal expansion control valve

4. Reverse cycle heat pump system

5. Reverse cycle heat pump system without refrigerant receiver

6. Drawing Mollier Chart

7. Calculating system performance

8. Comparison of system performance

9. Comparison of energy between cooling and heating experiments

10. Coefficient of performance (COP) and energy efficiency ratio (EER)

1. All system components, including condenser, compressor, evaporator, capillary tube, filter, refrigerant receiver, accumulator, hand valves, pressure gauges, expansion devices, are mounted on the front panel for direct operation and observation

2. Provide three types of expansion devices, including capillary tube, pressure expansion valve, and thermal expansion valve for refrigerant to pass through.

3. Provide 6 sight glasses to observe the refrigerant status before and after passing evaporator, condenser, expansion devices, and compressor.

4. Provide high and low pressure protection switches to automatically halt the compressor when detecting wrong refrigerant flowing path.

5. The refrigerant path for high pressure tube is painted in red and low pressure tube in blue.

6. Use touch panel control and display data

7. Can use the VNC for wireless control.(Need use the WIFI AP)

2. Provide three types of expansion devices, including capillary tube, pressure expansion valve, and thermal expansion valve for refrigerant to pass through.

3. Provide 6 sight glasses to observe the refrigerant status before and after passing evaporator, condenser, expansion devices, and compressor.

4. Provide high and low pressure protection switches to automatically halt the compressor when detecting wrong refrigerant flowing path.

5. The refrigerant path for high pressure tube is painted in red and low pressure tube in blue.

6. Use touch panel control and display data

7. Can use the VNC for wireless control.(Need use the WIFI AP)